Prior to shipment, it is essential to plan the truckload efficiently, the logic being to maximize the usable space in a truck. While weight & freight class are necessary but the volume occupied by each object is also an important pricing factor. The dimensional weight of a box is used to factor out the weight of the box, which will help in calculating how much amount has to be paid to ship the package.

If the anticipated box dimension measurement is different from the actual, the shipment will have to be measured again which may lead to the final price being adjusted. The company’s entire plan for loading trucks will have to be re-done and it may throw off the budget or the deadline, so the measurements have to be as precise as possible.

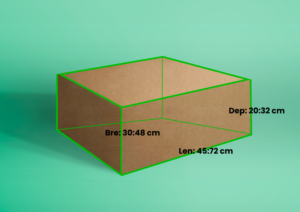

Currently, the box dimensions measurement process is done manually which consumes a lot of time and effort. The length (L), Breadth (B) & Height (H) are calculated in inches/cms. For irregularly shaped boxes, extreme points have to be used for measurement. Multiplying L*B*H gives you the cubic inches of the shipment. This process has to be repeated for all the boxes and at the end adding them all together.

TechVision+ automation helps you reduce manual work effort and improve speed and quality of your operations with intelligent vision

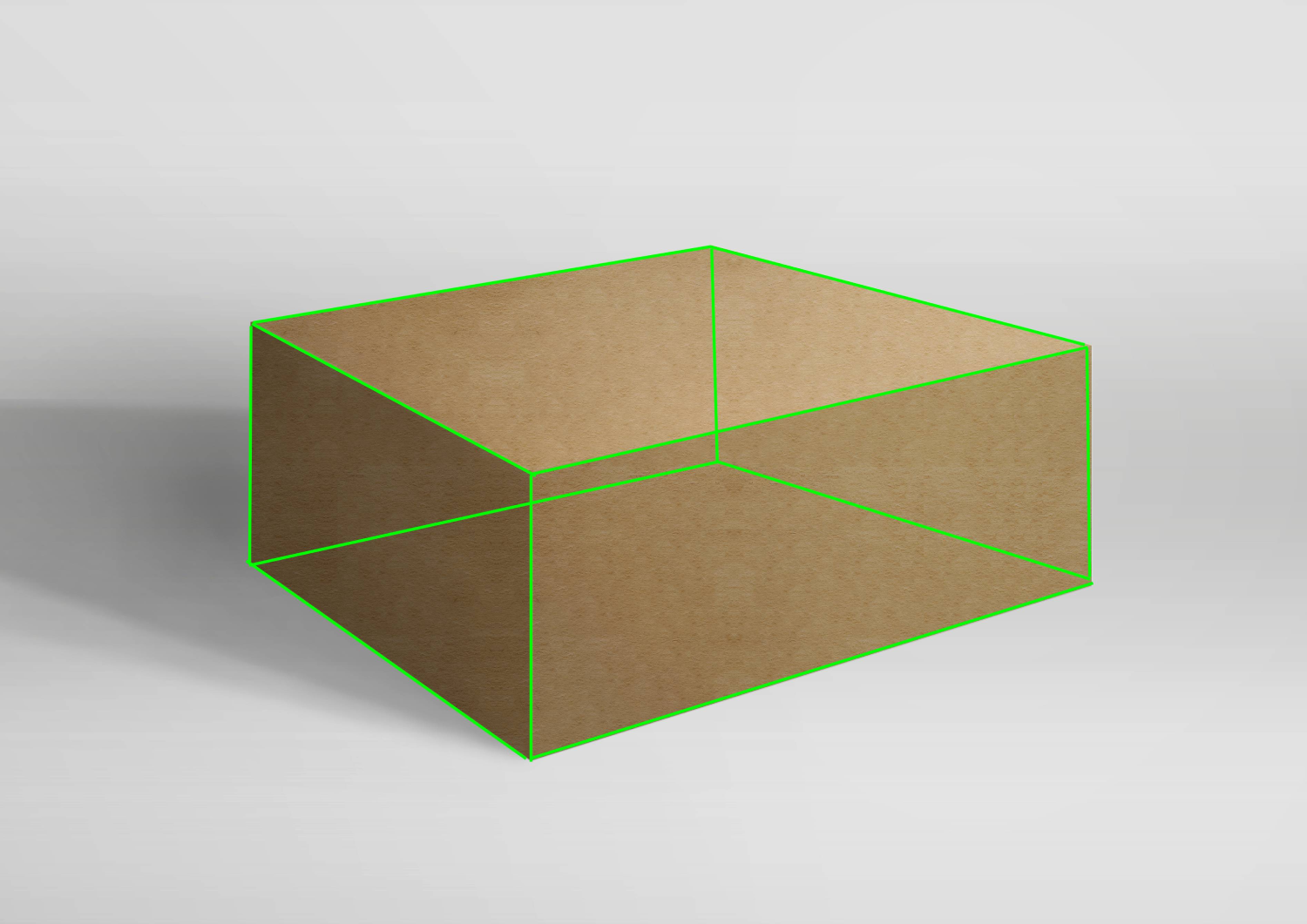

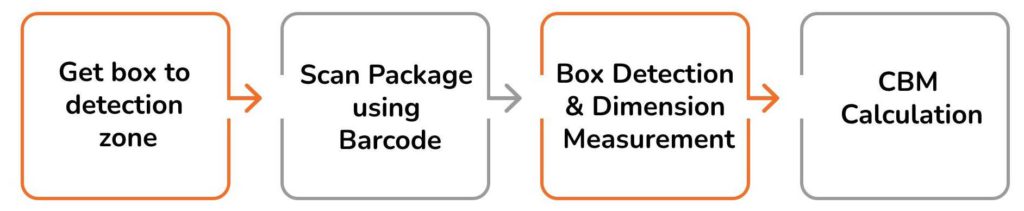

TechVision+ proposes automating the process of capturing box dimensions using AI and Computer Vision. A video of the box is captured using a Depth Camera to calculate the length, breadth, and height automatically. This data is updated in the WMS/TMS using API integration.

Process:

The dimensions calculated using our computer vision algorithms can be used for optimizing the space for cartonization, palletization, and loading space on a truck. It is also used to identify damaged boxes.

Benefits

- Auto measurement of Package Dimensions leading to productivity & operational efficiency

- Cost savings, especially from LTL Load Optimization

- Over 90% reduction in time for calculating and planning compared to manual measurement methods