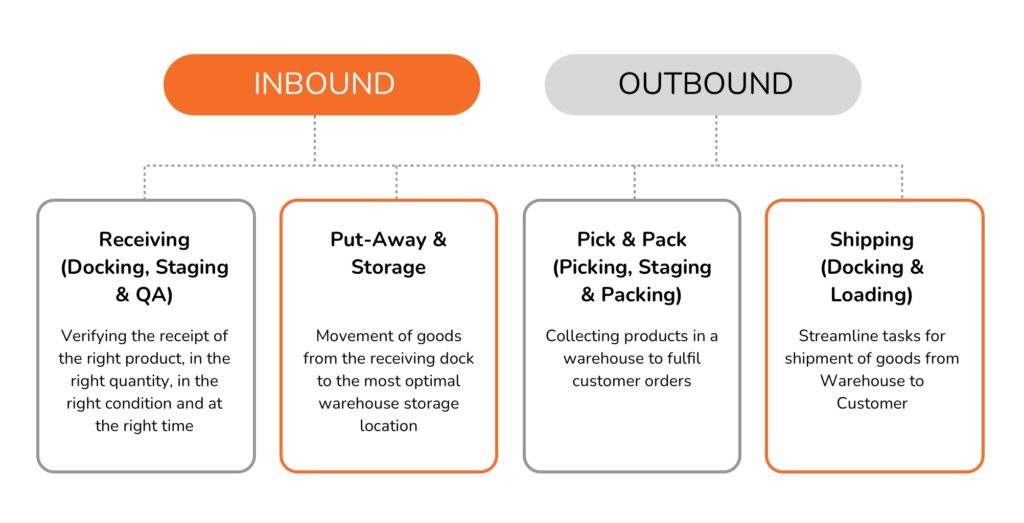

The warehouse is accountable for the goods received by them to be maintained in proper condition until they are shipped. Product packaging is an important element for maintaining quality which makes QC a necessary function in a warehouse. There are two primary processes involved in a warehouse, Inbound (Receiving to Put-Away) and Outbound (Pick & Pack to Shipment).

TechVision+ leverages intelligent vision, cameras, and IoT tags to help you ensure the quality of packed goods are maintained.

QC of Packed Goods

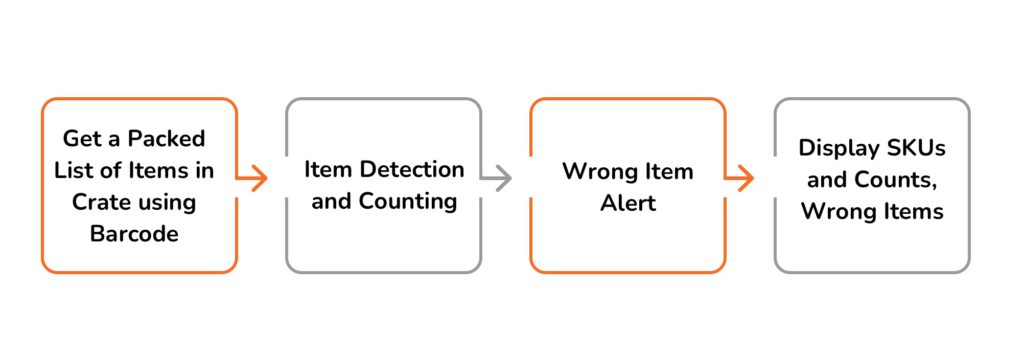

Typically, warehouse staff look at an order and the SKUs to be packed, and perform the following manual tasks:

- They pick and scan the item before placing it in the box being packed

- This is repeated for all items packed in the box

- For a box of 24 items, it takes about two minutes to pack one order

TechVision+ intelligent solution for QC uses deep learning to detect and count the items in a few seconds optimizing the time taken up to 50%.

Benefits

- Increases customer confidence and the company’s credibility

- Improve work processes and efficiency

- Reduced returns from customers

- Reduces cost associated with returned items

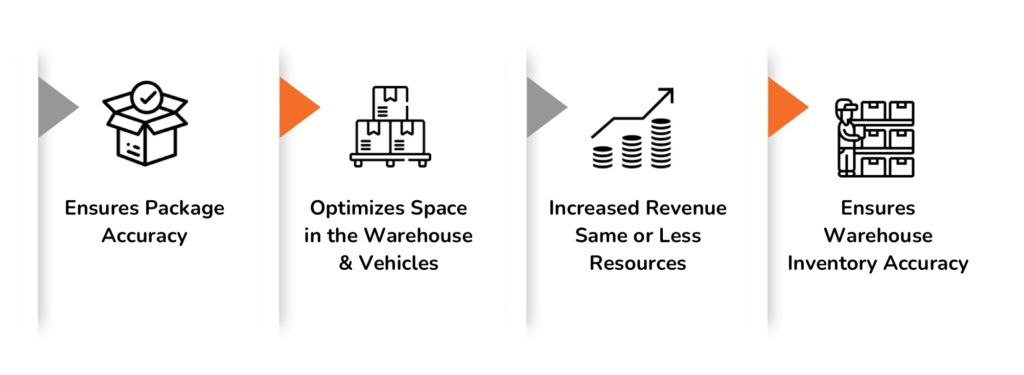

Intelligent Vision for Better Outcomes

TechVision+ helps in automating package verification, optimizing the pick and pack process, and tracking people and vehicles in the warehouse utilizing innovative Intelligent Vision solutions.